Combatting Deep vein thrombosis on planes through renewable energy, environmental awareness and corporate social responsibility.

FLYING PEDALS

Design Brief : To create a product that both helps improve the overall health of passengers and the environmental footprint of airlines.

Product Overview: Flying Pedals is a footrest pedal system. It allows the individual to flex their foot backward and forwards, flexing their calves, thereby reducing DVT. The pedal motions creates energy, which contributes to the powering of lights.

Year : 2023

DISCOVER & DEFINE

Research was conducted to find the major problems passengers and airlines face whilst flying.

RESEARCH

-

Deep vein thrombosis (DVT) occurs when a blood clot forms in a deep vein in your body. These become exceedingly problematic when the clot is lodged into the lungs. Research shows that 1 in 6000 people get DVT on planes due to poor circulation and extenuating health circumstances.

Similarly, studies found that 97% of passengers that travelled for more than 7 hours experienced swelling of extremities (Da Silva et al, 2021). This can cause discomfort on and off the plane.

Current solutions to both DVT and swelling include the use of compression socks and regular movement on planes.

-

In 2016, Australian international and domestic airlines contributed to 22 million tonnes of CO2 emissions, equating to 3% of Australia’s total emissions (Australian Government, 2019). It was projected that this figure would rise 2 - 3% until 2035 (Australian government, 2023).

Contrastingly, Australian international passenger airlines have made a commitment to have net zero emissions by 2050. This aims to be done through more fuel-efficient planes and carbon emission offsets (Australian government, 2023).

This, however, begs the question whether this commitment can be fast-tracked through different methods. Especially through the rise of international and domestic travel around the world.

-

With the rise of the importance of CSR, airlines have started to act more responsibly. This can include net zero emissions, more sustainable fuel, zero waste and the mitigation of single-use plastics.

However, individuals that fly airlines have little knowledge of this and how they can contribute to this cause. Currently, individuals can pay to off-set their emissions, but little discussion is placed around this.

DESIGN CRITERIA

Research was analysed to create the main design criteria for the project.

-

Create a design that considers the ergonomics of the user. With a health focus in mind, the device should promote health and help individual live a better life.

-

Create something that promotes discussion and awareness of health and sustainability issues when flying.

-

Create something that helps airlines be more socially responsible. This can include renewable energy production and carbon offsets.

A series of mapping was then conducted to ideate potential opportunities. Based on mind mapping, the areas that can be successfully impacted include health and environmental factors. Similarly, the. ain opportunity areas relate to create a leg circulation device and a product that better improves

MIND MAPPING, SYSTEMS PROCESS MAPPING (IDENTIFICATION OF PAIN POINTS & OPPORTUNITIES)

DEVELOP

SKETCHING

Initial sketches were made to create iterations of the pedal design and layout of product.

CAD

CAD was used to make iterations of the design. This included shape, ergonomics and aesthetics.

MANUFACTURING

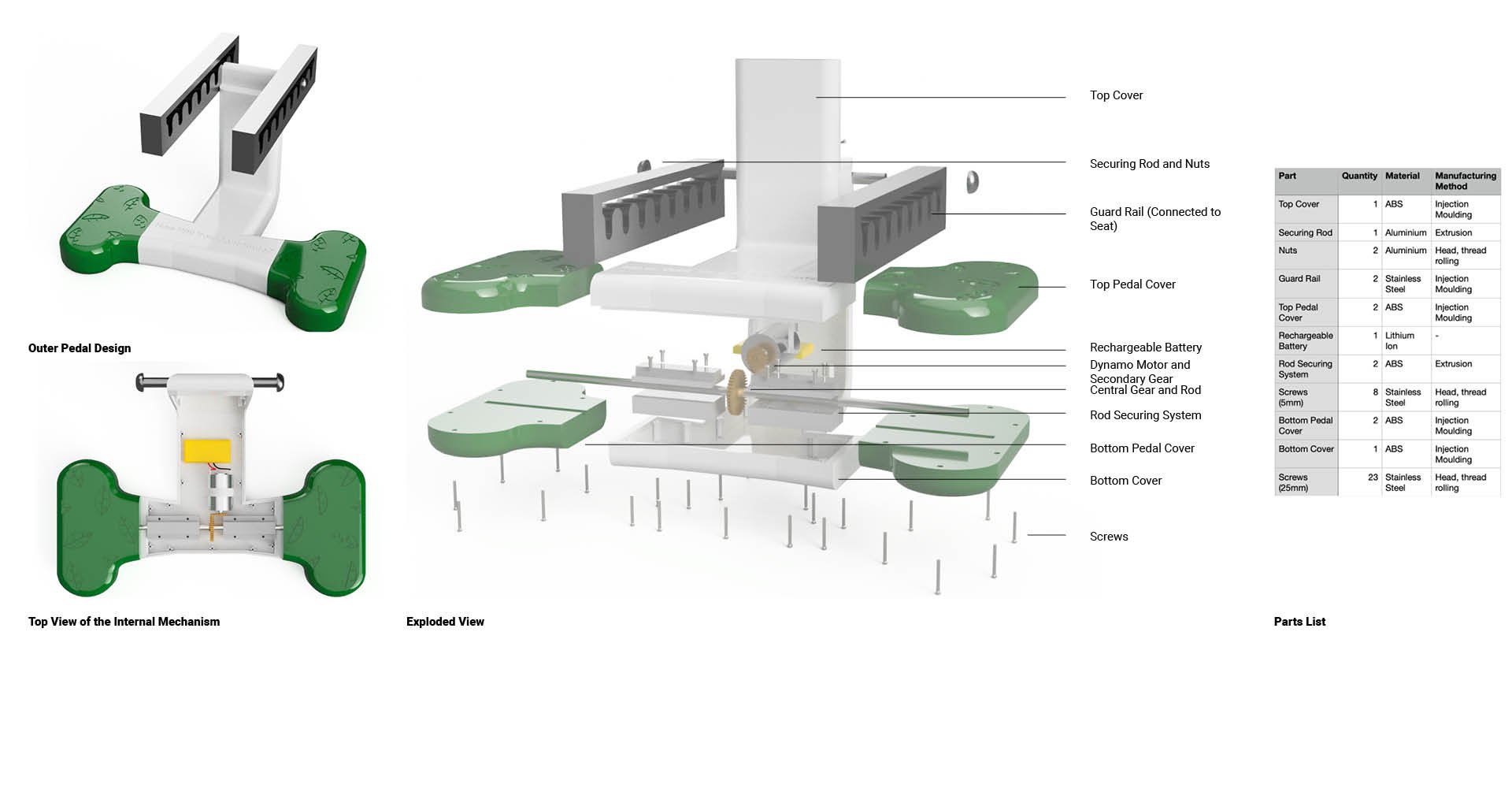

Internal manufacturing layouts and connection to the seat were considered. The goal was to make a compact setup that could move and rotate.

DELIVER

KEY CHARACTERISTICS

After completing the earlier stages of the design process, a product called FLYING PEDALS was made to solve the initial problem. FLYING PEDALS is a foot-rest pedal that enables individuals to flex their calves to increase blood flow and decrease swelling, contributing to reducing DVT.

Below are the key characteristics of the design that meet the design criteria and help solve the initial problem.

-

Flying pedals enables the user to flex their feet. Once the feet are flexed, the calves contract. This promotes circulation, decreasing swelling and the chance of DVT.

-

Footrests can be adjusted forwards and backwards to account for different leg sizes. The pedals are wide enough to accommodate different-sized feet. The pedal itself can also be used as a footrest, allowing variability in use.

Future iterations will allow the pedals to go up and down as well.

-

As individuals pedal, energy is created. This can contribute to the powering of the plane’s lights. Through the small screen to the right of the main screen, individuals can see how much energy they have created and how that contributes to their offset of emissions. This, therefore, creates a tangible way for individuals can contribute.

Although not a large amount of energy is created, it shows that airlines are committed to individuals’ health and their carbon footprint. Thereby showing their commitment to corporate social responsibility.

-

When a passenger boards the plane, they will see the pedal and see the phrase “How can you contribute”. This firstly creates discussion around what the pedal is. Similarly, as they start pedalling and creating energy, it promotes discussion about energy creation and the offset of their carbon footprint.

SEQUENCE OF USE

A manufacturing overview can be found below. Flying pedals utilises a dynamo motor to create kinetic energy. As the individual flex their calves and turns the pedals forward and backward, the rod with gear attached turned the dynamo motor and gear. This energy is stored in a rechargeable battery that powers the lights. The two pedals are attached with a screw system that attaches them to the central rod. The top and bottom covers, as well as the pedal covers are attached with screws. The main components are made using injection moulded recycled Acrylonitrile Butadiene Styrene Plastic (ABS).

MANUFACTURING